P/M TOOL AND STEEL ROLLS

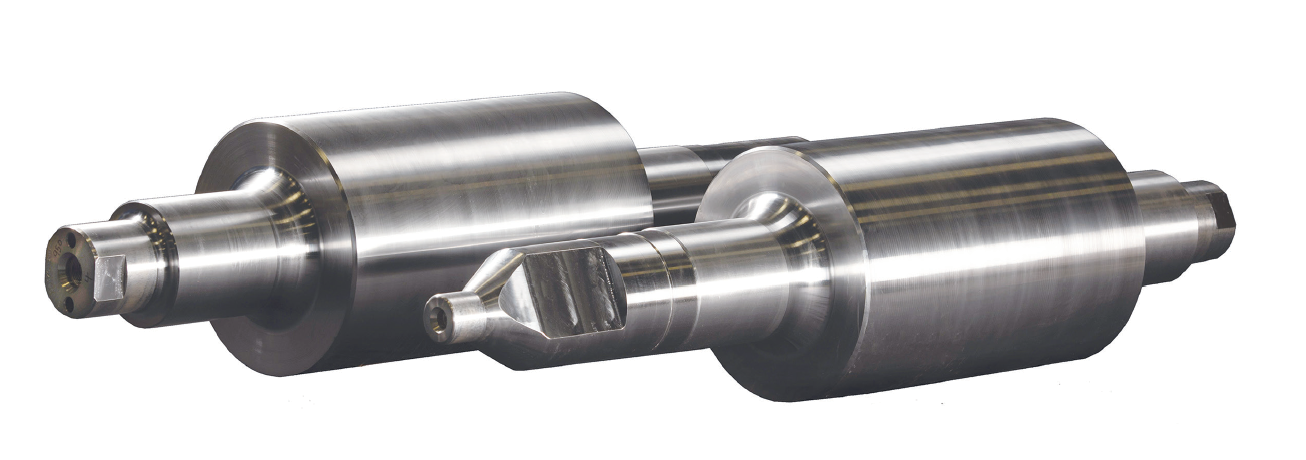

Leadar Roll manufacturers high wear resistant rolls in a variety of high-performance steels. We use our experience, knowledge, and our ability to partner with our customers to determine the best grade for each unique need. With an average increase in life of three (3) to six (6) times the life of a conventional iron roll, it is easy to see why these rolls have gained such increased popularity over the last twenty years. Leadar’s Composite Bonded Roll (CBR) is a single roll with a high-performance working surface and a high strength roll neck for use in an everyday steel mill. This design uses a process of hot isostatic pressing of powder material onto a steel shaft to alleviate the need for a mechanical locking mechanism. This also allows for the roll to contain the same number of passes as a conventional iron roll (i.e. no space is used for a locking mechanism). With our powder metal technologies we can offer high hardness materials up to 70 HRC.

These rolls use a balance of homogenously combined fine-grained carbon and vanadium, which enhances the toughness and provides a heat check resistance that results from normal rolling in a mill. This allows for superior dimensional stability, easy machinability, and toughness over that of a conventional or other tool steel roll. The powdered metallurgy tool steel roll is able to be utilized in most applications that are running over 2.5 meters per second.